SMART. SIMPLE. SAFE.

No more estimating. Our digitally-integrated solutions deliver accurate, real-time data, taking the guesswork out of bulk material handling and processing.

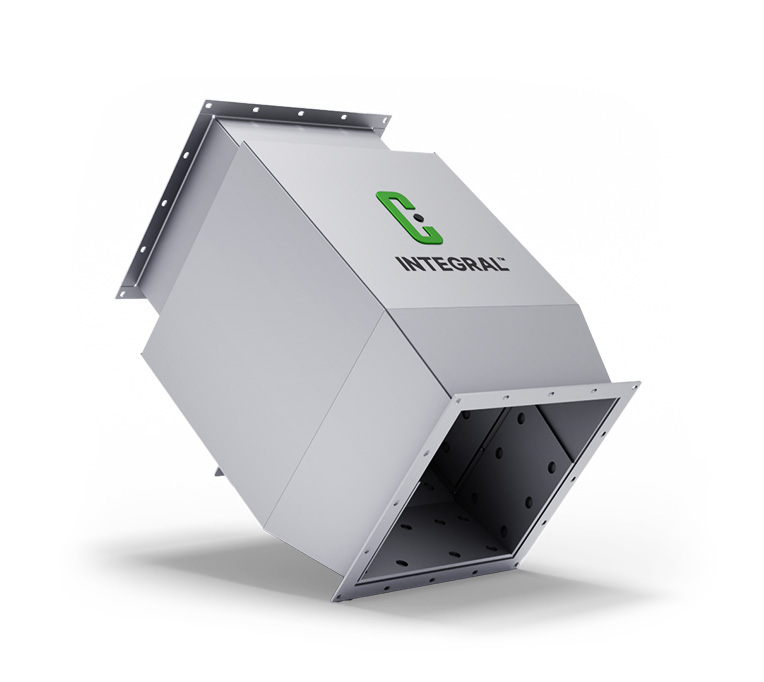

INTEGRAL SERIES

Our Integral Flow Sensors are designed for incline applications to capture real-time flow rate and total weight measurement with typical accuracy within +/-1%.

The compact design of the flow sensor and touchscreen PLC controller allows for flexible placement to capture data at the plant operator, or enterprise level.

The Integral Flow Sensors are suitable for installation into existing spouts and chutes without the need for adjusting geometry.

Designed for dry flowable materials like seed, grain, and minerals without features that can damage the commodity. Integral Flow Sensors are able to measure a broad range of flow rates from 800 to 50k lbs/minute.

| MODEL | Low Operating Range (lbs/min)* | High Operating Range (lbs/min)* | Inlet/Outlet Pipe Size (diameter round/square)* | Configuration | Flow Sensor Dimensions (L x W x H) | Flow Sensor Weight (lbs) |

|---|---|---|---|---|---|---|

| INTEGRAL NR/2K | INTEGRAL NRL/2K | 800 | 2,000 | 6″ OD | Round | 32 1⁄8″ x 13″ x 11 5⁄8″ | 67 | – |

| INTEGRAL NS/5K | INTEGRAL NSL/5K | 1,750 | 5,000 | 9 3⁄4″ x 9 3⁄4″ ID | Square | 30 3⁄8″ x 16 1⁄4″ x 15″ | 135 | 200 |

| INTEGRAL NS/20K | INTEGRAL NSL/20K | 5,000 | 20,000 | 17 3⁄4″ x 17 3⁄4″ ID | Square | 36 1⁄2″ x 23 5⁄8″ x 24 3⁄4″ | 210 | 275 |

| INTEGRAL NS/50K | INTEGRAL NSL/50K | 17,500 | 50,000 | 29 3⁄4″ x 29 3⁄4″ ID | Square | 36 1⁄2″ x 37″ x 35 5⁄8″ | 375 | 425 |

Ready to optimize your operational efficiency?

Sign up today to learn more about our digitally integrated flow sensor technology and what it can do for your operation.

CONNECT WITH CONFIDENCE

Experience the enhanced capabilities of CADARO through our flexible CADARO CONNECT plans, tailored to meet your specific operational needs.

All CADARO products include a 1-year subscription to the CADARO CONNECT plan of your choice.

Via initializing inputs and outputs

Set batch weight target with setpoint based on % or lbs to control sliding gate or other mechanisms as desired

For cleaning or auxiliary output for custom use

Digital input for binary pushbutton or auxiliary output for custom use

Gain remote access to the screen view/control and data logging

Allow operators to view data and control functions remotely from the master device

Display active flow rate and batch

total weight

Optional: Custom Marquee data

Via initializing inputs and outputs

Set batch weight target with setpoint based on % or lbs to control sliding gate or other mechanisms as desired

For cleaning or auxiliary output for custom use

Digital input for binary pushbutton or auxiliary output for custom use

Gain remote access to the screen view/control and data logging

Allow operators to view data and control functions remotely from the master device

Display active flow rate and batch

total weight

Optional: Custom Marquee data

Via initializing inputs and outputs

Set batch weight target with setpoint based on % or lbs to control sliding gate or other mechanisms as desired

For cleaning or auxiliary output for custom use

Digital input for binary pushbutton or auxiliary output for custom use

Gain remote access to the screen view/control and data logging

Allow operators to view data and control functions remotely from the master device

Display active flow rate and batch

total weight

Optional: Custom Marquee data

Complete Annual Hardware, Software & Support Plan

The CADARO COMPLETE plan provides the ultimate value for dry bulk material handling operations, accelerating your Return on Investment. CADARO COMPLETE includes your choice of the flow sensor unit, a PLC control box, ENTERPRISE software, and remote service support.

Via initializing inputs and outputs

Set batch weight target with setpoint based on % or lbs to control sliding gate or other mechanisms as desired

For cleaning or auxiliary output for custom use

Digital input for binary pushbutton or auxiliary output for custom use

Gain remote access to the screen view/control and data logging

Allow operators to view data and control functions remotely from the master device

Display active flow rate and batch total weight

Optional: Custom Marquee data