CADARO Newsletter | Volume 1 – December 2024

Welcome to the first edition of CADARO’s newsletter, where we bring you the latest insights into flow sensor technology and innovations. At CADARO, we are driven by a strong commitment to clarity, accuracy, and efficiency—qualities that empower bulk material handlers and processors to achieve new levels of operational excellence.

Our CADARO flow sensors are designed with seamless integration in mind, allowing you to enhance your new and existing facilities without the need for major adjustments. Featuring a compact design and a user-friendly touchscreen PLC controller, our flow sensors provide flexible placement options while delivering real-time, accurate measurements of flow rates and weight.

The benefits are clear:

- Enhanced Efficiency: Our sensors provide real-time data that helps you make informed decisions, reducing downtime and improving overall productivity.

- Increased Profitability: Minimize waste and maximize output yields.

- Effortless Integration: Transition smoothly without disrupting operations.

With CADARO, you are not just adopting innovative technology, you are investing in solutions that can transform your dry bulk material handling operations.

Stay tuned for more updates, insights, and success stories in the coming editions. We look forward to partnering with you on your journey toward greater efficiency and profitability.

Company Updates & News

Upcoming Event: GEAPS Exchange 2025

February 22-25, 2025

Kansas City Convention Center

Kansas City, Missouri, USA

https://www.geaps.com/exchange/

GEAPS Exchange 2025 is quickly approaching, and we cannot wait! Our President and CEO, Royce Schulte, alongside our CTO, Josh McGuire, will be presenting an Innovation Station on Monday, February 24 10:30-11:15 a.m.:

Measurement in Motion – Using Flow Sensors to Future-Proof Your Operation:

Grain handling and processing operations need to be future-ready, today. Is your operation ready for a shrinking workforce, additional regulations, and other external pressures? Could you quickly adapt to remain competitive as the industry evolves? What happens when the “guy who’s always done it” retires or is promoted? This session will demonstrate how grain handling operations can future-proof your business operations.

We hope to see you there!

Customer Spotlight

Hereford Ethanol Partners, L.P. (HEP), Hereford, TX

Early Adopter of CADARO Flow Sensor Enabling Automated Truck Loading

In October 2021, Hereford Ethanol Partners (HEP) faced the challenge of efficiently loading upwards of 100 trucks daily. They designed a truck loading system that automated the process, enabled driver self-loading, and seamlessly integrated CADARO’s flow sensor into their existing systems. This led HEP to purchase and integrate a CADARO INTEGRAL NSL20K flow sensor.

Impressive Outcomes with CADARO Flow Sensor

- 60 million Bushels Handled: HEP has efficiently handled an estimated 60 million bushels, showcasing the system’s reliability and capacity.

- Driver-Driven Automation: Drivers independently oversee loading processes using the CADARO flow sensor when coupled with Vertical Software Inc. automation software, reducing labor dependency and streamlining operations.

- Enhanced Efficiency: Automated systems adapt in real time, reducing downtime, minimizing waste, and optimizing resource utilization—all while scaling easily to meet workload growth.

Transforming Truck Loading Operations with CADARO COMPLETE Plan

HEP has consistently embraced innovation in their truck loading operations. Their decision to upgrade their CADARO INTEGRAL NSL 20K unit under the CADARO COMPLETE Plan has further enhanced their efficiency and performance.

CADARO’s Collaboration with Hereford

- Commissioned a new INTEGRAL NSL20K as part of our CADARO COMPLETE Plan, which includes a flow sensor, PLC Control Box, the latest CADARO Enterprise software, and remote support.

- Provided ongoing support, enabling Hereford to calibrate and enhance loading accuracy and repeatability.

- Identified and implemented enhanced software opportunities, driving overall performance improvements.

Performance Results

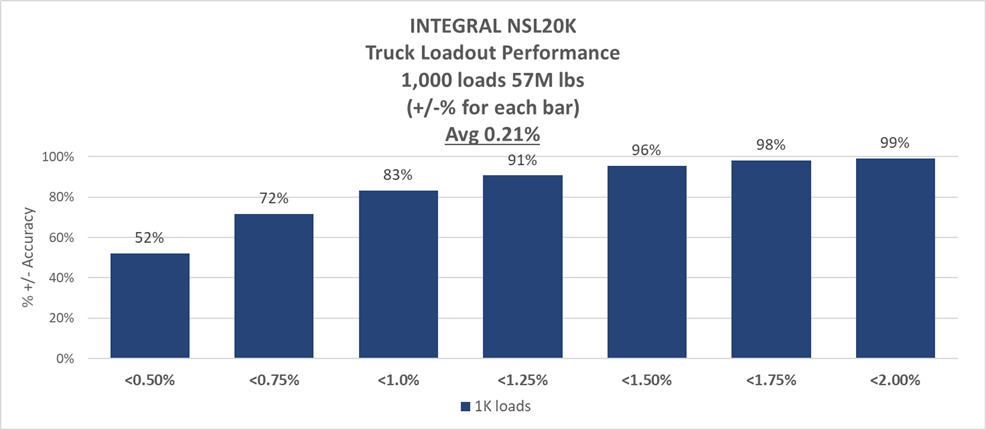

The following chart demonstrates the results of HEP’s truck loading operations using the upgraded CADARO INTEGRAL NSL20K system for an initial 1,000 loads, totaling 57 million lbs. Performance is measured by the percentage of loads within specific range categories (± %).

Key Points

- Range Categories: The x-axis represents range categories, from less than ±0.50% to less than ±2.00%.

- Accuracy Trends:

- The blue bars represent the percentage of 1,000 loads completed within each range using the INTEGRAL NSL20K system.

- Performance Highlights:

- At lower range (e.g., <±0.50%), the INTEGRAL NSL20K achieved 52% of loads.

- The average performance for the system was within 0.21% of actual scale generated weight.

- CADARO NSL20K delivers ± 1% typical accuracy claimed.

The CADARO INTEGRAL NSL20K system has demonstrated reliable measurements for automated truck loading through the collaborative relationship between HEP and CADARO as part of the CADARO COMPLETE Plan.

HEP exemplifies the power of forward-thinking automation. By leveraging the CADARO COMPLETE Plan, they continue to set a new standard in truck loading operations—defined by precision, efficiency, and consistency. Automation is not just about technology; it is about results. HEP’s innovation and adoption of automation technology continue to maximize efficiency and resource utilization, resulting in a remarkable ROI. The CADARO ROI Calculator lets you calculate the potential ROI of our flow sensors, including a five-year cumulative projection. Try the calculator today!

Industry Insights

What is driving automation?

- Automation in grain handling and processing is being driven by several key industry factors. One of the primary drivers is the need for increased efficiency and productivity. As the global demand for grain continues to rise, operations must optimize their processes to manage larger volumes more quickly and accurately. Automation technologies, such as automatic controllers and variable frequency drives, enable facilities to streamline operations, reduce manual labor, and minimize errors, leading to significant improvements in throughput and overall efficiency.

- Another critical driver is the emphasis on safety and regulatory compliance. Grain handling can be hazardous, with risks including grain dust explosions and worker injuries. Automation reduces the need for human intervention in dangerous tasks, thereby enhancing workplace safety. Additionally, automated systems help facilities comply with stringent regulations by providing precise control and monitoring of processes, ensuring that safety standards are consistently met. This not only protects workers but also helps companies avoid costly fines and disruptions.

- Finally, the push for better data management and decision-making is a significant factor driving automation. Modern automated systems are equipped with advanced sensors and data analytics capabilities that provide real-time insights into operations. This data-driven approach allows managers to make informed decisions, optimize resource allocation, and predict maintenance needs before they become critical issues. By leveraging these technologies, grain handling and processing facilities can achieve greater operational transparency, improve inventory management, and enhance overall profitability.

Implementing automation does not have to mean overhauling an entire operation. In fact, success often lies in identifying and automating straightforward processes first. These simpler systems can create immediate gains in efficiency, laying a solid foundation for further improvements. Gradually stacking these small wins results in cumulative, transformative change across an organization.

For example, automating a truck loading process, as demonstrated by CADARO’s flow sensor technology, eliminates inefficiencies in material handling while maintaining scalability. These targeted solutions not only reduce labor costs but also deliver precision and consistency, providing measurable ROI from day one.

The path to effective automation starts with partnering with experienced vendors. Collaborating with experts ensures that every stage—design, installation, commissioning, and optimization—is handled with precision. Experienced partners can identify the most impactful areas to automate and create a roadmap that balances immediate gains with long-term growth.

By collaborating with knowledgeable vendors, businesses can avoid costly pitfalls and maximize the benefits of automation. These partnerships provide ongoing support, helping companies continuously refine their systems and adapt to changing needs.

Automation is not just about technology; it is about empowering businesses to operate smarter, safer, and more sustainably. By starting with simple, achievable opportunities and collaborating with experts, companies can unlock the full potential of automation. The result? Optimized efficiency, reduced costs, and a future-proof operation ready to tackle the challenges of tomorrow.

The future belongs to those who innovate. With automation, industries can turn challenges into opportunities and stay ahead in an ever-evolving landscape.

Contact Us

If you are interested in learning more about how CADARO flow sensors can benefit your operations, please reach out to discuss your needs and how we can assist.

WE MEASURE. YOU MANAGE.